What are the differences between the substrate, cover film, and PI reinforcement of an FPC (flexible printed circuit) board?

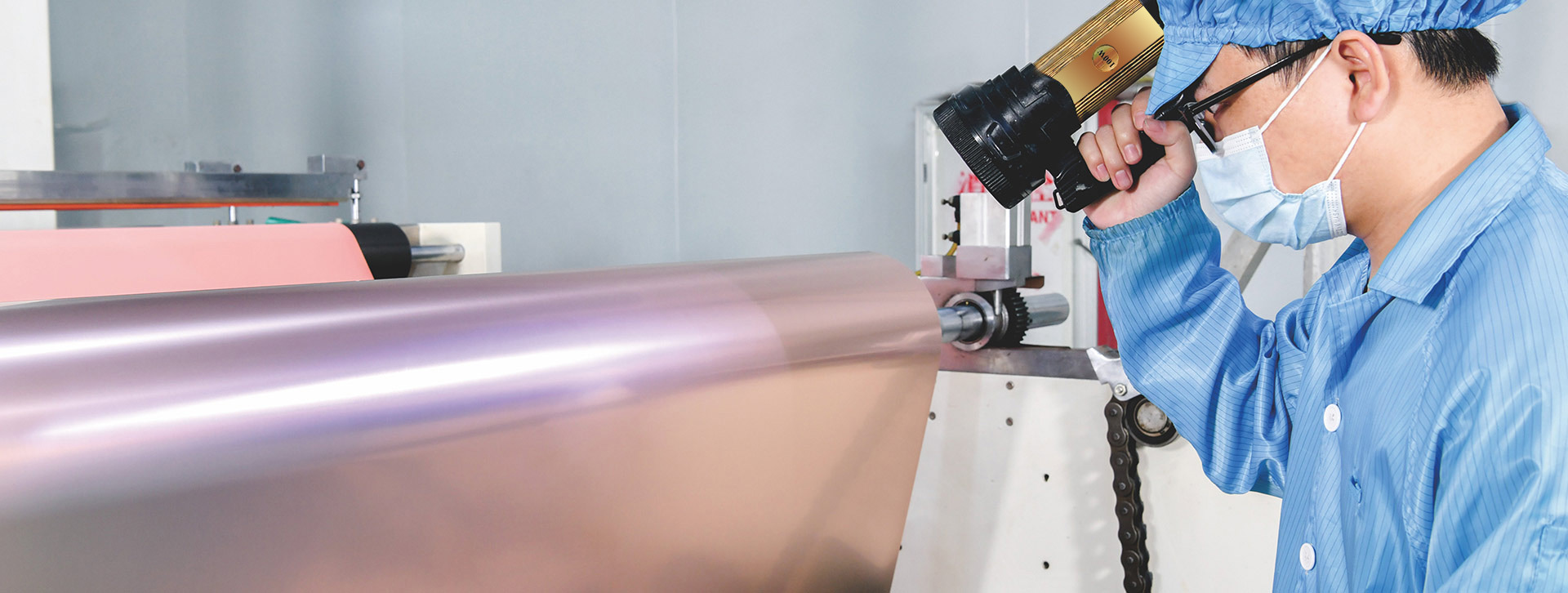

FPC flexible circuit boards are highly reliable and flexible printed circuit boards made with PI polyimide or polyester film as a substrate. They feature high wiring density, light weight, thin thickness, and good bending properties. PI, as a special engineering material, has been widely used in aerospace, microelectronics, nanotechnology, liquid crystal, separation membrane, and laser fields. The long-term operating temperature range is -200℃~426℃. PI polyimide is commonly found in FPC flexible circuit boards, present in the substrate, cover film, and even reinforcement. Some may find this confusing, so let's discuss their differences today.

2021-11-09

FPC flexible circuit boards are made with PI polyimide or polyester film as the substrate. They are highly reliable, flexible printed circuit boards with high wiring density, light weight, thin thickness, and good bending properties. PI, as a special engineering material, has been widely used in aerospace, microelectronics, nanotechnology, liquid crystals, separation membranes, lasers, and other fields. Long-term use temperature is -200℃~426℃. PI polyimide is very common in FPC flexible circuit boards, existing in the substrate, cover film, and even reinforcement. Some may be confused about the differences, so let's discuss them today.

Functional differences between the substrate, cover film, and PI reinforcement of FPC flexible circuit boards:

1. PI Substrate: FPC flexible circuit board substrates are divided into two types: adhesive substrates and adhesive-free substrates. Whether it's an adhesive substrate or an adhesive-free substrate, PI polyimide is essential.

2. PI Cover Film: Its main function is circuit insulation.

Thickness differences between the substrate and cover film of FPC flexible circuit boards:

1. PI Substrate: For the PI in the substrate, 1/2mil and 1mil are common, and the thickness can even reach 4mil and 5mil (DuPont adhesive-free PI material).

2. PI Cover Film: There are two thickness options for the PI cover film: 1/2mil or 1mil.

Color selection differences between the substrate and cover film of FPC flexible circuit boards:

1. PI Substrate: No color options.

2. PI Cover Film: PI cover film has three color options: yellow, white, and black.

FPC flexible circuit boards are printed circuits made with flexible insulating substrates, possessing many advantages not found in rigid printed circuit boards. They can be freely bent, wound, and folded, arranged as needed according to spatial layout requirements, and moved and extended in three-dimensional space, achieving integrated component assembly and wire connection; using FPCs greatly reduces the size and weight of electronic products, suitable for the development of electronic products towards high density, miniaturization, and high reliability. Therefore, FPCs are widely used in aerospace, military, mobile communications, laptops, computer peripherals, PDAs, digital cameras, and other fields or products; FPCs also have good heat dissipation and solderability, easy assembly, relatively low comprehensive costs, and soft-hard combined designs to some extent compensate for the slightly insufficient component load-bearing capacity of the flexible substrate.

Previous Article:

Related Information

FPC substrate polyimide film covering film

Polyimide film covering film for FPC substrate - covering film for flexible printed circuit boards

Flexible circuit board structure and substrate

Flexible printed circuits are classified according to the number of conductive copper foil layers, including single-layer boards