Flexible circuit board structure and substrate

Flexible printed circuits are classified according to the number of conductive copper foil layers, including single-layer boards

2025-03-21

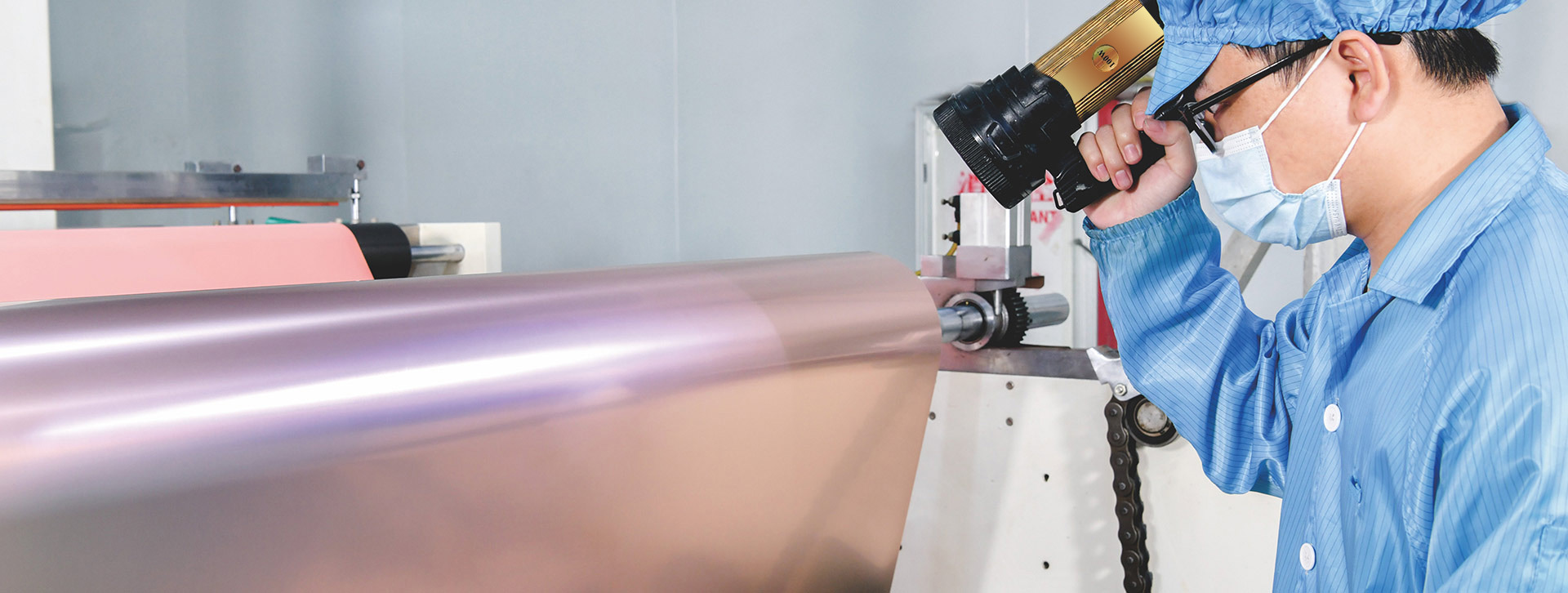

Flexible printed circuits are classified according to the number of conductive copper foil layers, including single-layer boards, double-layer boards, multilayer boards, and double-sided boards. Single-layer board structure: This structure is the simplest type of flexible printed circuit. Typically, the substrate + adhesive + copper foil is a purchased raw material set, and the protective film + adhesive is another purchased raw material set. First, the copper foil undergoes etching and other processes to obtain the required circuit, and holes are drilled in the protective film to expose the corresponding pads. After cleaning, the two are combined using a rolling method. Then, gold or tin plating is applied to the exposed pads for protection. In this way, the large board is made. It is usually also punched into small circuit boards of the corresponding shape. There is also a method that does not use a protective film but directly prints a solder resist layer on the copper foil, which reduces the cost, but the mechanical strength of the circuit board is reduced. Unless the strength requirements are not high, but the price needs to be as low as possible, it is best to use the method of applying a protective film. Double-layer board structure: When the circuit lines are too complex, a single-layer board cannot be wired, or a copper foil is needed for grounding shielding, a double-layer board or even a multilayer board is needed. The most typical difference between a multilayer board and a single-layer board is the addition of a through-hole structure to connect the various layers of copper foil. Generally, the first processing technology of the substrate + adhesive + copper foil is to make through-holes. Holes are drilled in the substrate and copper foil, and after cleaning, a certain thickness of copper is plated, and the through-holes are made. The subsequent manufacturing process is almost the same as that of a single-layer board. Double-sided board structure: The double-sided board has pads on both sides, mainly used for connection with other circuit boards. Although its structure is similar to that of a single-layer board, the manufacturing process is very different. Its raw materials are copper foil, protective film + adhesive. First, holes need to be drilled in the protective film according to the pad position requirements, then the copper foil is attached, the pads and leads are etched, and then another protective film with holes drilled is attached.

Previous Article:

Next Article:

Related Information

FPC substrate polyimide film covering film

Polyimide film covering film for FPC substrate - covering film for flexible printed circuit boards

Flexible circuit board structure and substrate

Flexible printed circuits are classified according to the number of conductive copper foil layers, including single-layer boards