01

Compliant with ROHS requirements,

Free of substances of very high concern (SVHC) in REACH regulations;

02

Higher thermal conductivity than ordinary aluminum-clad copper clad boards,

Effectively increasing the service life of electronic products;

03

Electromagnetic wave shielding and excellent cost performance;

04

Good machinability, excellent dimensional stability,

Contains ceramic heat dissipation filler.

01

ROHS compliant,

Free of SVHCs listed in REACH regulations;

02

Higher thermal conductivity than ordinary aluminum-clad copper clad laminates,

Effectively increases the service life of electronic products;

03

Electromagnetic wave shielding and excellent cost performance;

04

Good machinability, excellent dimensional stability,

Contains ceramic heat dissipation filler.

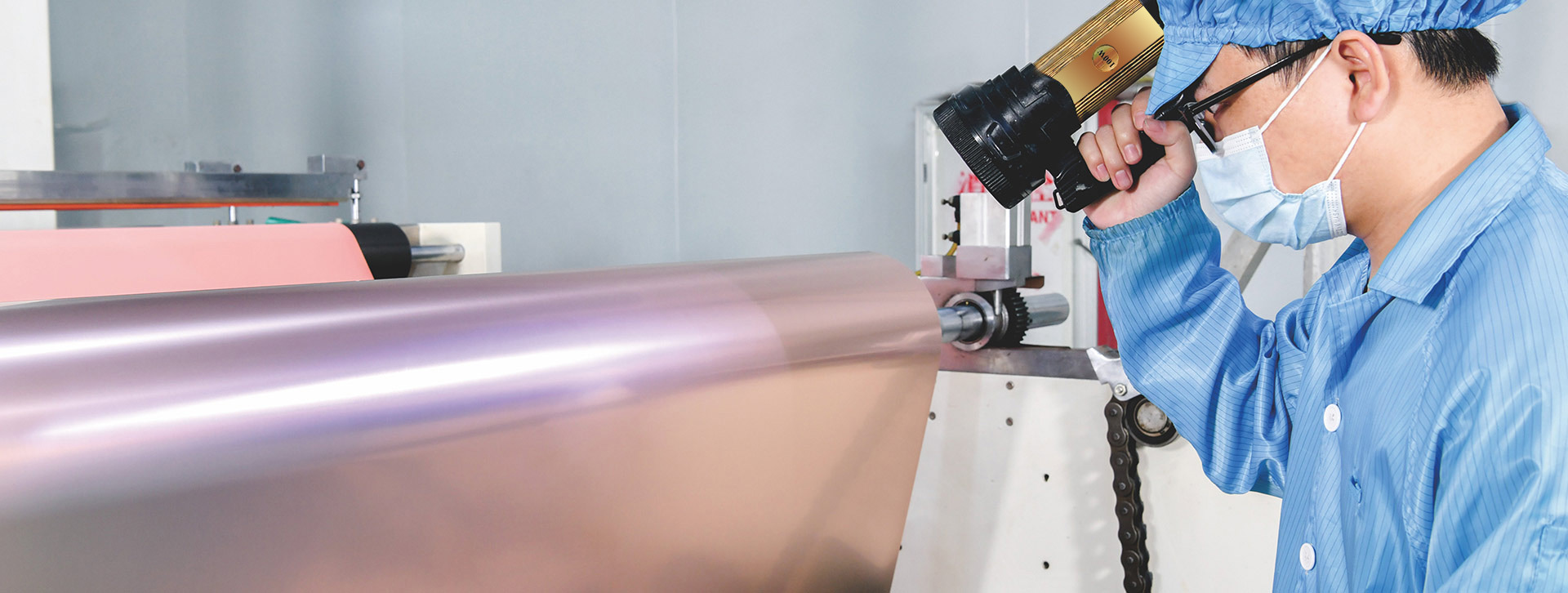

Aluminum-clad copper clad laminate is a special type of printed circuit board. Its substrate is metal (usually aluminum, copper or other alloys), instead of the traditional epoxy glass fiber board. The characteristic of metal-clad copper clad laminate is its better heat dissipation performance. It is mainly used in high-power lamps such as LED lighting, LED street lights, LED stage lighting, automotive electronics, backlights, and other products.

| Item | Unit | Test method | Standard | Test value |

| BEGETE | ||||

| Warping |

% | IPC-TM-650 2.4.22.1 | Thickness≥0.80mm:≤2.0% Thickness≤0.80mm:≤1.5% |

0.6-1.2/0.5-1.0 |

| Dielectric layer thickness |

um | IPC-TM-650 2.2.18.1 | ±10% | ±10% |

| Thermal stress |

S | IPC-TM-650 2.4.13.1 | ≥30S | >300S |

| Peel strength (1Oz) |

N/mm | IPC-TM-650 2.4.8.1 | ≥1.0 | 1.3 |

| Withstand voltage |

KV(DC) | IPC-TM-650 2.5.6 | ≥5.0(120μmAd) | 5.0 |

| Breakdown voltage |

KV(AC) | IPC-TM-650 2.5.6 | ≥3.0(120μmAd) | 3.5 |

| Comparative Tracking Index (CTI) |

V | IEC60112 | ≥400 | 600 |

| Glass transition temperature TG(DSC) |

℃ | IPC-TM-650 2.4.25 | / | 120 |

| Coefficient of Thermal Expansion CTE(TMA) |

'%(50~260℃)' | IPC-TM-650 2.4.24 | ≤0.5 | 0.3 |

| Surface resistance |

MΩ | IPC-TM-650 2.5.17.1 | / | 3.96x109 |

| Volume resistivity |

MΩ·cm | IPC-TM-650 2.5.17.1 | / | 1.68x1011 |

| Insulation resistance |

Ω | JIS6481-1996 | / | 1.46x1011 |

| Dielectric constant |

/ | IPC-TM-650 2.5.5.9 | ≤6.0 | 5.8 |

| Dissipation factor |

/ | IPC-TM-650 2.5.5.9 | ≤0.045 | 0.040 |

| Water absorption |

% | IPC-TM-650 2.6.2.1 | ≤2.0 | 0.15 |

| Insulation thermal conductivity |

W/m·k | ASTM D 5470 | / | ≥4.05 |

| Insulation thermal resistance |

K·㎡W | / | ≤0.3x10 -4 | 0.26x10 -4 |

| Flammability |

/ | UL94 | UL94 V-0 | UL94 V-0 |

BEGETE 5.0W aluminum-clad copper clad laminate

Category

Keywords

Related Products

BEGETE 8.0W aluminum-clad copper clad laminate

Aluminum-clad copper clad laminate is a special kind of printed circuit board. Its substrate is metal (usually aluminum, copper, or other alloys), instead of the traditional epoxy fiberglass board. Metal-clad copper clad laminates are characterized by better heat dissipation performance and are mainly used in high-power lamps such as LED lighting, LED streetlights, and LED stage lighting, as well as automotive electronics and backlights.

Excellent peel strength and flexibility; Excellent value for money; Excellent electrical properties and insulation; Excellent dimensional stability; Flame retardant: UL94-VO Transmittance >90%

Ultrathin Wireless Charging Black Cover Film Series

Excellent peel strength and flexibility; Excellent value for money; Excellent electrical properties and insulation; Excellent dimensional stability; Flame retardant: UL94-VO Transmittance > 90%

High-frequency, high-speed, flexible copper-clad laminate series

Excellent peel strength and flexibility; Excellent value for money; Superior electrical properties and insulation; Excellent dimensional stability; Flame retardant: UL94-VO; Transmittance >90%