01

Compliant with ROHS requirements,

Free of substances of very high concern (SVHC) in REACH regulations;

02

Higher thermal conductivity than ordinary aluminum-clad copper clad boards,

Effectively increasing the service life of electronic products;

03

Electromagnetic wave shielding and excellent cost performance;

04

Good machinability, excellent dimensional stability,

Contains ceramic heat dissipation filler.

Product Features

Excellent peel strength and flexibility;

Excellent value for money;

Excellent electrical performance and insulation;

Excellent dimensional stability;

Flame retardant: UL94-VO

Transmittance >90%

| Model/Material MATERIAL/TYPE | JRDE121212 | JRDE252018 | JRDE252035 | IPC standards or industry requirements | ||||

| PI(um) | 13 | 25 | 75 | ±5% | ||||

| TPI(um) | 12*2 | 20*2 | 20*2 | ±5% | ||||

| Release film(um) | 12*2 | 35*2 | 18*2 | ±5% | ||||

| Usage layer(um) | 61 | 135 | 151 | ±5% | ||||

| Adjustable according to customer requirements Thickness range | ||||||||

| Test Item | Property | Property | Property | IPC standards or industry requirements | ||||

| Peel strength(kgf/cm) | 1.1 | 1.3 | 1.5 | ≥0.7 | ||||

| Heat resistance | 230℃/10s Pass | 230℃/10s Pass | 230℃/10s Pass | 230℃/10s Pass | ||||

| Dimensional stability(Method B) | MD(%) | ±0.08 | ±0.08 | ±0.08 | ±0.15 | |||

| TD(%) | ±0.05 | ±0.05 | ±0.05 | ±0.15 | ||||

| Chemical resistance | HCL 2mol/L | Peel Decline rate(%) |

4.6 | 4.5 | 4.7 | ≤20 | ||

| NaOH 2mol/L | 4.5 | 4.6 | 4.6 | ≤20 | ||||

| IPA | 4.3 | 4.5 | 4.3 | ≤20 | ||||

| Inter-wire insulation resistance (Ω) | 4.65x1010 | 5.83x1010 | 4.31x1010 | ≥1.0x10° | ||||

| Surface resistance (Ω) | 4.14x1013 | 4.06x1013 | 5.26x1013 | ≥1.0x10 10 | ||||

| Volume resistance (Ω.cm) | 5.01x1014 | 5.33x1014 | 5.15x1014 | ≥1.0x10 12 | ||||

| Dielectric constant (10MHz) | 3.5 | 3.5 | 3.5 | ≤4.0 | ||||

| Dissipation factor (10MHz) | 0.031 | 0.029 | 0.032 | ≤0.04 | ||||

| Flame retardancy | Complies with UL94-V0 standard | Complies with UL94-V0 or VTM-0 standard | ||||||

| Environmental requirements | Complies with ROHS, REACH standards and halogen-free requirements | Complies with ROHS and halogen-free requirements | ||||||

| Shelf life | 20±10℃、50±20%RH | 12 months | 12 months | 12 months | 12 months | |||

Flexible copper-clad laminate PET double-panel series

Category

Keywords

Related Products

BEGETE 8.0W aluminum-clad copper clad laminate

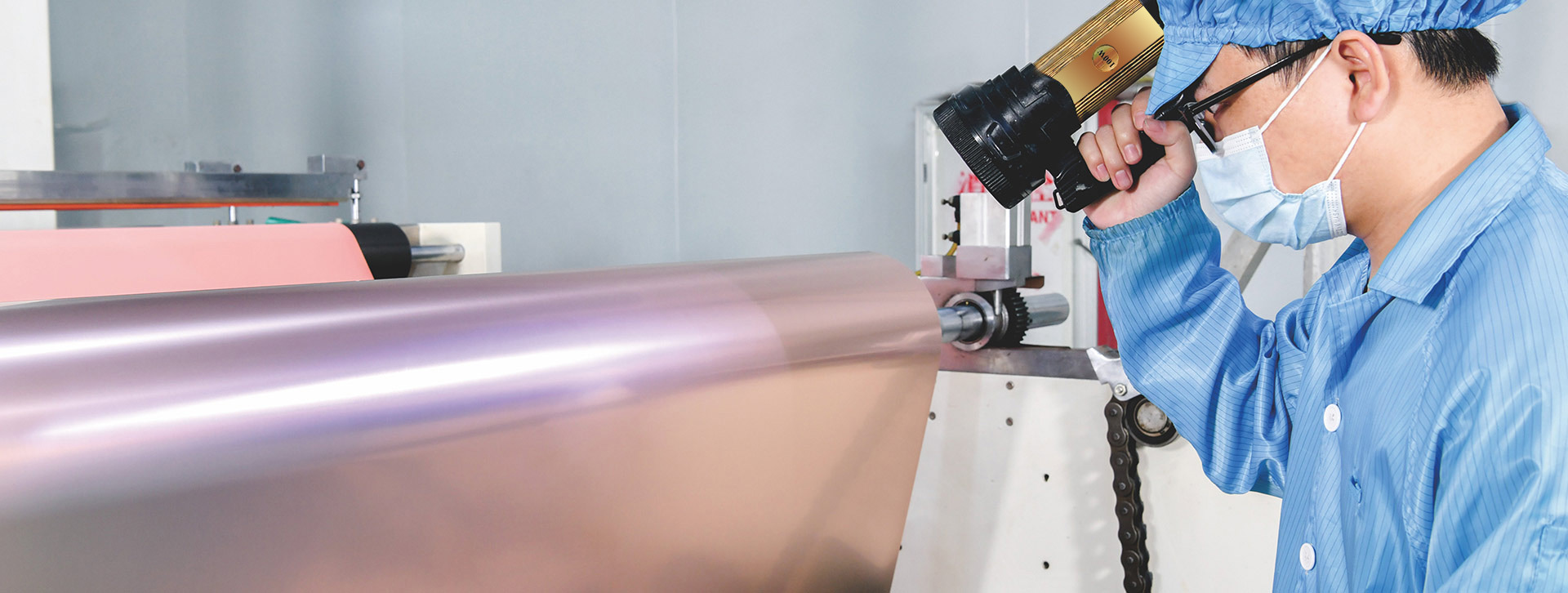

Aluminum-clad copper clad laminate is a special kind of printed circuit board. Its substrate is metal (usually aluminum, copper, or other alloys), instead of the traditional epoxy fiberglass board. Metal-clad copper clad laminates are characterized by better heat dissipation performance and are mainly used in high-power lamps such as LED lighting, LED streetlights, and LED stage lighting, as well as automotive electronics and backlights.

Excellent peel strength and flexibility; Excellent value for money; Excellent electrical properties and insulation; Excellent dimensional stability; Flame retardant: UL94-VO Transmittance >90%

Ultrathin Wireless Charging Black Cover Film Series

Excellent peel strength and flexibility; Excellent value for money; Excellent electrical properties and insulation; Excellent dimensional stability; Flame retardant: UL94-VO Transmittance > 90%

High-frequency, high-speed, flexible copper-clad laminate series

Excellent peel strength and flexibility; Excellent value for money; Superior electrical properties and insulation; Excellent dimensional stability; Flame retardant: UL94-VO; Transmittance >90%