Application advantages and development prospects of FPC flexible printed circuit boards?

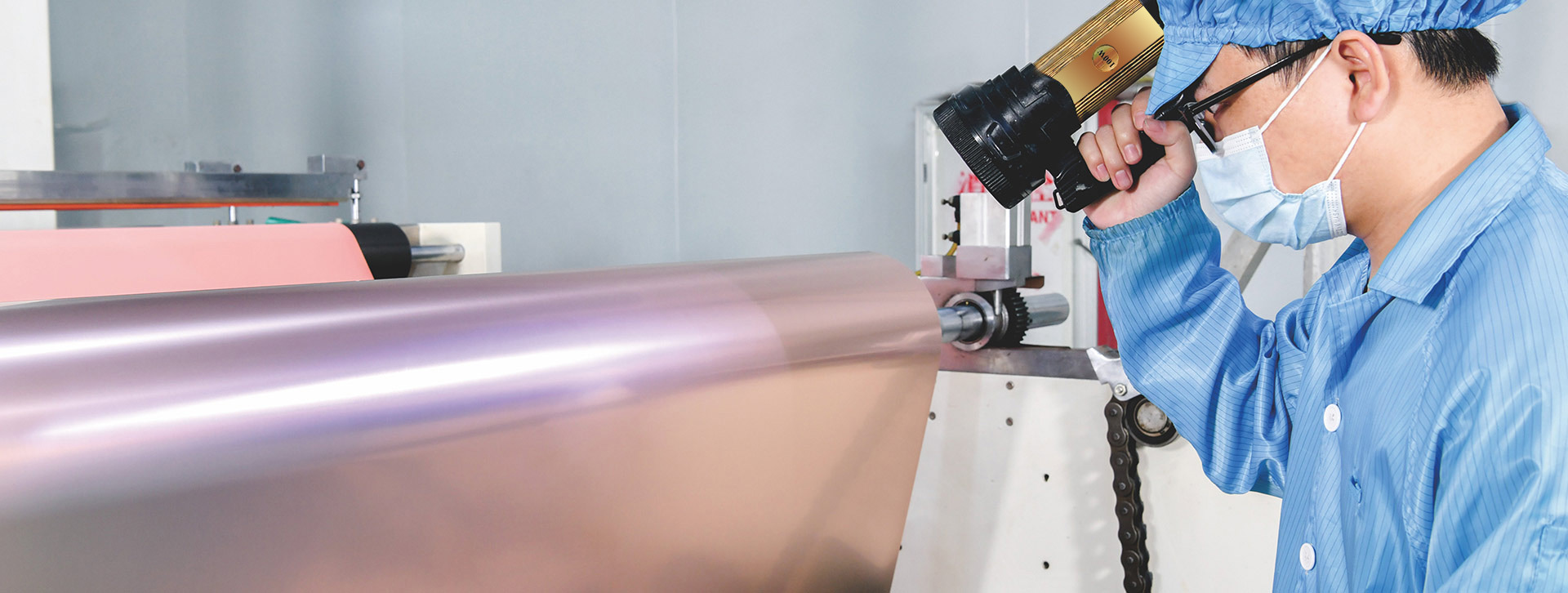

With the updating and upgrading of electronic products, FPC flexible printed circuits have, owing to their unique advantages, met the development trend of electronic products being light, thin, short, and small, playing an important foundational role in the field of electronic information industry. FPC flexible printed circuits are mainly used for the connection of electronic products, acting as a medium for signal transmission, featuring high reliability and excellent flexibility. With the continuous advancement of informatization and intelligence construction, the market demand for FPC flexible printed circuits will also become increasingly large.

2021-11-12

With the upgrading and iteration of electronic products, FPC flexible printed circuits, with their unique advantages, have met the development trend of electronic products being lighter, thinner, shorter, and smaller, playing an important foundational role in the electronic information industry. FPC flexible printed circuits are mainly used for connecting electronic products, acting as a medium for signal transmission, and possessing high reliability and excellent flexibility. With the continuous advancement of informatization and intelligent construction, the market demand for FPC flexible printed circuits will also become increasingly large.

The demand for FPC flexible printed circuits in the electronics industry is growing. Firstly, due to the excellent characteristics of FPC flexible printed circuits themselves, they are suitable for the ultra-thin requirements of electronic products; secondly, in high-frequency and high-speed transmission of circuits, the reliability requirements for FPC flexible printed circuits are high. Therefore, the market size of FPC flexible printed circuits in the electronics industry is continuously expanding. The advantages of FPC flexible printed circuits include high wiring and assembly density, eliminating the need for extra wiring connections; good bending properties, high softness, and high reliability; small size, light weight, and thin thickness; circuit setting, increased wiring layers and elasticity; simple structure, easy installation, and consistent connection.

The application fields of FPC flexible printed circuits can be divided into three categories: smartphones, wearable devices, and automotive electronics. Applications in smartphones cover battery modules, display modules, touch modules, camera FPCs, and connection modules, with a single smartphone requiring 10-15 FPC flexible printed circuits. With the commercialization of 5G, the miniaturization and large-screen development of smartphones, and the rise of foldable screen phones, the usage of FPC flexible printed circuits will increase. The demand for FPC flexible printed circuits in the smartphone sector is constantly rising.

Besides mobile phones, the automotive electronics market is also a major battlefield for FPCs. In-vehicle control systems, such as instrument panel displays, air quality systems, audio systems, monitors, and sensors, require high signal transmission volume and high reliability, allowing FPCs to demonstrate their advantages. With the emergence of new electronic products, the market and applications of FPC flexible printed circuits are also expanding, and the upgrading and iteration of different types of electronic products will bring more promising development prospects than the traditional market.

Previous Article:

Next Article:

Related Information

FPC substrate polyimide film covering film

Polyimide film covering film for FPC substrate - covering film for flexible printed circuit boards

Flexible circuit board structure and substrate

Flexible printed circuits are classified according to the number of conductive copper foil layers, including single-layer boards