What are the components of FPC processing costs?

While the printed circuit board industry employs some common basic processes

2021-11-12

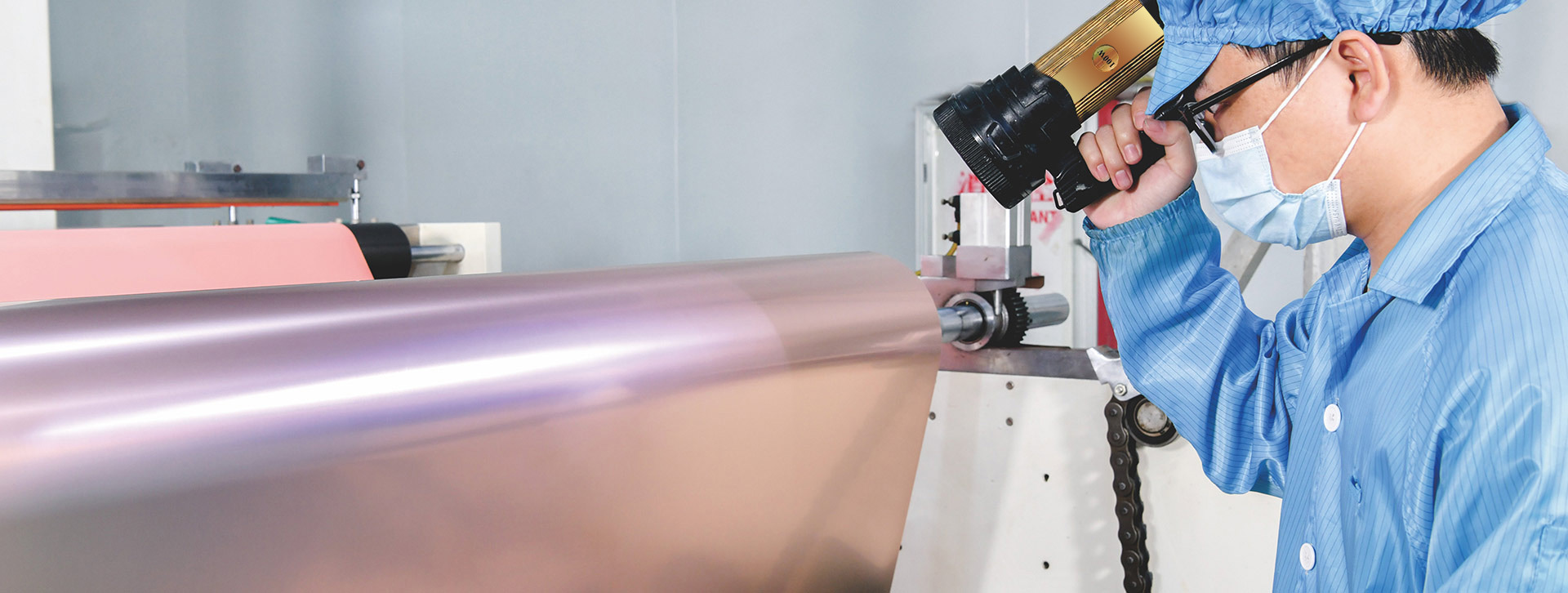

While the printed circuit board industry employs some common basic processes, the most crucial aspect is determining different production processes and equipment based on substrate thickness and material, precision requirements for line width and spacing, design structure, production scale, and other specific customer requirements. This leads to significant cost variations in FPC production. FPCs are highly customized products, with numerous cost components. For novice purchasers in electronics factories, it's essential to understand the cost components of FPC flexible circuit boards before prototyping.

The production process for FPC flexible circuit boards is complex, typically involving over 40 processes, including inner layer production, exposure, lamination, drilling, and electroplating. Taking FPCs as an example, typical processes include exposure, development, etching, copper plating, and stripping. Although FPCs are highly customized, these basic processes are essential, with differences only in specific parameters. Each process in FPC production is relatively mature; therefore, cost control becomes the key differentiator in profitability among FPC flexible circuit board manufacturers. Cost control is reflected in all aspects of the flexible circuit board manufacturer's operations, directly depending on the company's management level and requiring attention to detail. BNY is a "specialized, refined, and new" manufacturer specializing in high-precision, multilayer PCBs, special processes/materials, and special PCBs, providing rapid prototyping and small to large batch services, focusing on PCBs others cannot handle.

Previous Article:

Related Information

FPC substrate polyimide film covering film

Polyimide film covering film for FPC substrate - covering film for flexible printed circuit boards

Flexible circuit board structure and substrate

Flexible printed circuits are classified according to the number of conductive copper foil layers, including single-layer boards