AI-driven PCB intelligent manufacturing revolution

DeepSeek's AI algorithm analyzes historical data and design rules to automatically optimize PCB routing

2021-11-12

DeepSeek's AI algorithm analyzes historical data and design rules to automatically optimize PCB routing, stacking structure, and signal integrity, significantly shortening design cycles and reducing error rates. For example, AI-driven electromagnetic and thermal simulation tools can quickly verify design feasibility, reducing the number of physical prototype tests and lowering costs.

This technology is particularly important for high-complexity PCBs (such as high-density HDI boards and IC substrates), and the improvement in design efficiency directly accelerates the R&D process of high-end products.

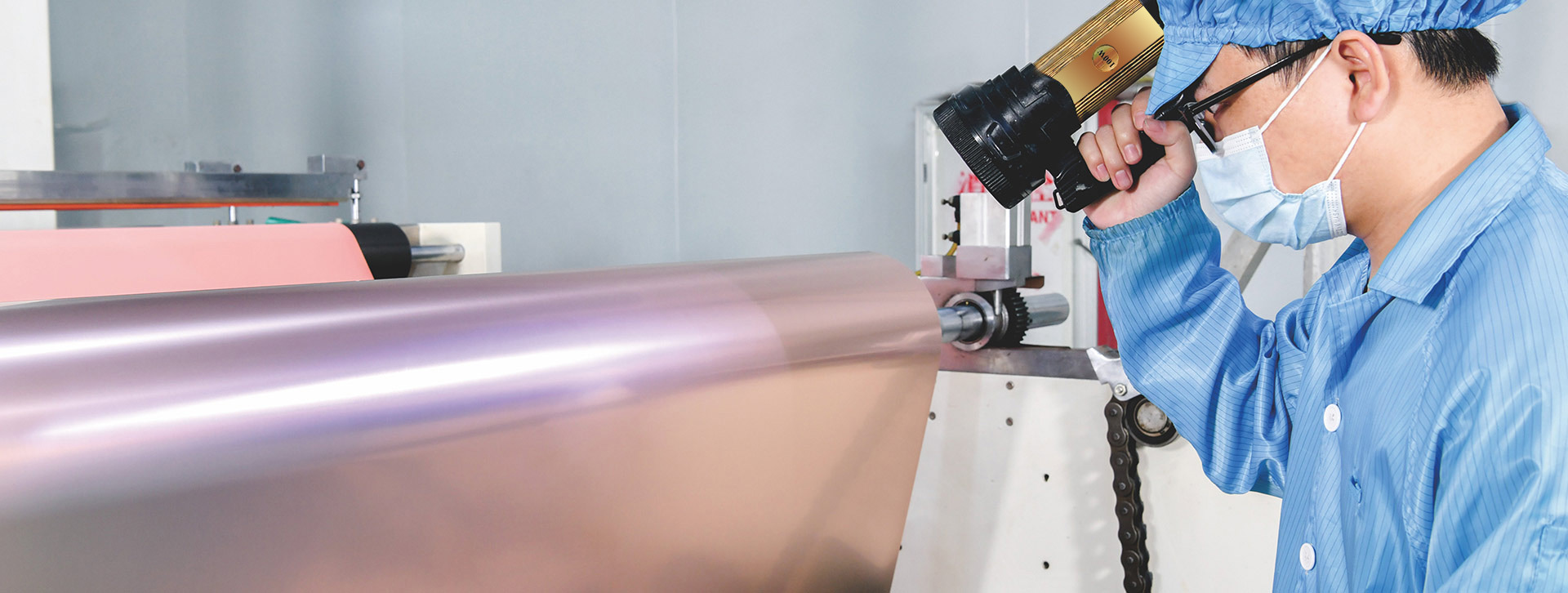

An AI-integrated machine vision system improves the accuracy and speed of PCB defect detection (such as short circuits, open circuits, and poor solder joints), reducing reliance on manual quality inspection. AI can also monitor production parameters (such as temperature and pressure) in real time, quickly locating the root cause of problems and reducing the defect rate. For example, companies like Shenzhen South Circuit, Shanghai HDI, and Baineng Cloud Board Smart Manufacturing Factory have seen a 5%-10% increase in yield and a 30% reduction in design cycle time by introducing AI technology.

II. Demand-Side Transformation: High-End and Diversification in Parallel

Although DeepSeek's low-cost model may reduce some computing power demand in the short term, its promotion of AI application popularization will stimulate the expansion of computing power infrastructure in the long term. For example, AI servers significantly increase the demand for high-frequency, high-speed boards (such as 16-layer or more HDI), with a unit price 3-5 times that of ordinary PCBs. It is predicted that the ultra-large-scale data center of the Stargate project alone could bring tens of billions of dollars in high-end PCB orders.

2. Intelligent Manufacturing and Quality Control

3. Predictive Maintenance and Process Optimization

DeepSeek's AI technology can analyze equipment sensor data to predict the failure risk of production equipment (such as drilling machines and etching lines), reducing downtime. In addition, machine learning can dynamically adjust key process parameters such as etching and plating, improving product consistency.

1. AI Computing Power Demand Drives High-End PCB Growth

2. Emerging Application Scenarios Expand Market Space

DeepSeek-driven applications such as edge computing and humanoid robots require more flexible PCB solutions. For example, Baineng Cloud Board Smart Manufacturing Factory has provided small-batch PCB products for the humanoid robot field, and the demand for flexible boards and rigid-flexible combination boards has increased. In addition, the explosive growth of IoT devices also requires PCBs with stronger data processing and interconnection capabilities.

3. Collaborative Upgrading of Materials and Packaging Technologies

High-performance packaging of AI chips (such as TSMC's CoWoS technology) requires supporting high-precision substrates, and substrates are essentially special PCBs. DeepSeek's technological innovation accelerates the vertical integration of the PCB and packaging industry chain, promoting the domestic substitution process of materials (such as low-loss high-speed substrates).

Previous Article:

Next Article:

Related Information

FPC substrate polyimide film covering film

Polyimide film covering film for FPC substrate - covering film for flexible printed circuit boards

Flexible circuit board structure and substrate

Flexible printed circuits are classified according to the number of conductive copper foil layers, including single-layer boards